Sour beers are a unique style of craft beer that have been gaining in popularity in recent years, resulting in many homebrewers researching how to brew a batch for themselves. In this post we are going to go over the step by step process of how to make a sour beer for yourself to include providing you with a delicious sour beer recipe you will truly enjoy.

Homebrewing a Sour Beer

Most homebrewers are timid of brewing a sour beer. There are a couple of reasons for this:

1 – The first being that there is a perceived added layer of complication to making a sour, which is partially true but as you will see with the method we discuss in this post making this beer is really not that hard.

2 – But the biggest reason most homebrewers stay clear of making this beer is the concern over their system becoming contaminated and that every beer they ever brew moving forward will be spoiled.

They believe that the bacteria and wild yeast that is used for making a sour will contaminate all of their brewing equipment and they will have to get rid of it all and start again.

The fact is that yes there is a small risk that this could happen, but if done the traditional way it is not likely.

There are two ways to make sour beers:

1 – There is the new method that a lot of impatient brewers are using which is the kettle sour method. It is a much faster method, however it is definitely more complicated and it does run the risk of contaminating your brewing equipment on both the hot and cold side.

2 – Then there is the traditional method which does take a longer amount of time but is the safest method, has a very small chance of contaminating your brewing equipment and arguably makes the best and most sought after sours.

While there are many delicious sours made using the faster kettle sour method, I recommend that you first try the traditional method, your patience will be rewarded.

Learn to Be Patient

Trust me I get it, one of the hardest parts of brewing is the waiting part. I can remember not too many years ago I would be in a rush to get through the fermenting and conditioning stages and get right to the taste testing and drinking stage as fast as possible.

My rush to get to the taste test ended up costing me in quality. Most alcohols do better with time. Although I still rush in some areas such as carbonating in the keg, when it comes to fermenting and conditioning I have learned to be patient and the quality of my beer has rewarded me ten fold.

When it comes to the traditional method of brewing a sour beer you are going to be forced to have patience. The wild yeast is going to demand that you do.

The traditional method will take a full 6 months to go from grain to glass. After the 6 months you can bottle or keg them. However you package your beer I would recommend that you also bottle some of the beer you make and put a few of the bottles away for 1-2 years and let them really condition. Like a fine wine the end result will be well worth the wait.

A Typical Brew Day

Although there is more complication involved when kettle souring your beer, with the traditional method brew day is the same as any other brew day.

You do not have to engage in any fancy mashing methods, just a straight old typical mash.

Brew yourself a simple beer recipe, keep it mild. Do not brew up an overly bitter or hoppy beer. Anything with too much taste will interfere with the souring when it comes to taste and result in beer you might not enjoy.

Ingredients to Brew a Sour Beer

Grains: for the grain bill keep it simple. Most people will use a pale malt such as Pilsner or 2-row along with some Wheat. Rice Hulls can be used also to prevent a stuck sparge. I also enjoy Carapils (dextrine) as it adds a little more body and head.

Hops: It is important to use low alpha acid hops with this beer. You do not want the sharp bitterness that the higher alpha hops will bring. Some brewers even recommend using any old hops you have kicking around, hops that you forgot to store in your fridge and have been sitting around for awhile actually work very nicely with this beer

Yeast: Here is where the fun starts. You will actually be using two types of yeasts. The first is good ol’ US-05. That will be the primary yeast that you ferment with in the primary fermenter.

The second yeast when you rack over to the secondary is going to be a lambic blend of Pediococcus (pedio), Brettanomyces (brett) and Lactobacillus (lacto). I recommend you use Wyeast 3278 Lambic Blend for this.

Sour on the Fermentation Side

So you have brewed up your beer the way you normally would on the hot side. We now move to the cold side i.e Fermentation. This is where we do things just a little bit different when making a sour beer.

The first 2-3 weeks of the fermentation stage is done the same as any other beer. Simply transfer your wort over to your fermenter and pitch “only” the US-05 and let it go to work eating the easy sugars for you.

After 2-3 weeks you have a choice, you can either pitch the Lambic yeast directly into the primary fermenter or you can rack it over to a secondary and pitch the yeast there.

The following are a couple of things to consider when making this decision:

If you are concerned about contaminating your brewing equipment this is when and where it can happen. Meaning anything the beer touches after adding the Lambic yeast can cause future contamination to beers you brew. This includes pieces of equipment such as the fermenter, any transfer hoses, your keg and/or bottles.

To prevent this from happening you can have dedicated equipment that you use for only brewing sour beers. An old fermenter, an old keg, separate bottles and transfer hoses.

Other options are to use glass carboys for fermenting, a good cleaning and sanitizing will in the majority of times get rid of the bacteria and wild yeast. It is the plastic fermenters and bottles that cause the greatest problems because it is hard to sanitize and clean in the scratches they all develop.

We brewed sours at my pub and used plastic speidel fermenters, the same transfer lines and the same kegs and had no problems with contamination. Why? Because we cleaned and sanitized all of the equipment very thoroughly.

Clean the equipment thoroughly with PBW and sanitize very well with starsan and you will be fine

The easiest method is to use a glass carboy for both the primary and secondary. Transfer to kegs and glass bottles. All of these clean and sanitize very well. The transfer line would be the only concern but fill it full of water with PBW and let it soak, drain it and refill it with starsan and let it sit for some time and you will be good to go.

The choice is yours my friend. Just know there is a slight risk of contamination, but it is easily minimized, take any of the above precautions and all should be fine.

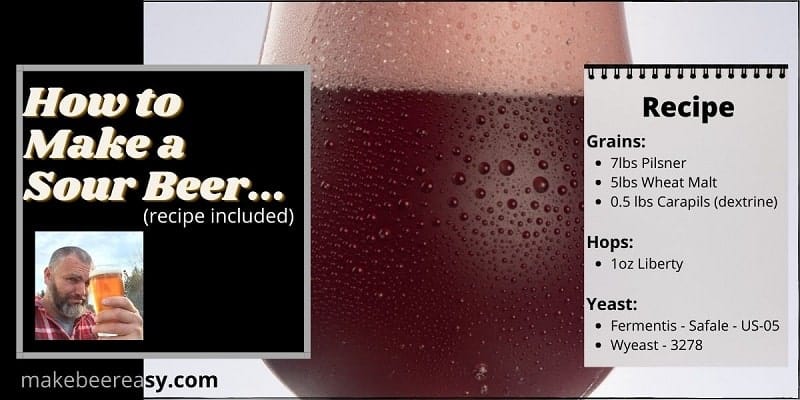

Sour Beer Recipe

Now that you know how to brew a sour beer it is time to actually brew one. The following recipe I call “Pucker Up Baby”, it’s a tasty recipe that I am sure you will like.

SRM: 3.82

Target OG: 1.057

Target FG: 1.011

ABV: 6.06%

IBU: 15.47

Pre Boil Volume: 6.25 gallons

Fermenter Volume: 5.2 gallons

Brew House Efficiency: 70%

Grains

- 7lbs Pilsner

- 5lbs Wheat Malt

- 0.5 lbs Carapils (dextrine)

Hops

- 1oz Liberty

Yeast

- Fermentis – Safale – US-05

- Wyeast – Belgian Lambic Blend 3278

Brewing Instructions

Mash your grains at 152 degrees Fahrenheit for 60 minutes.

Boil for 90 minutes, adding your hops at the start of the boil.

At the end of the boil cool wort down to yeast pitching temperature and transfer it to your fermenter and pitch the US-05 Ale Yeast.

Seal the fermenter and let it ferment for 14 days.

When the 14 days have passed you can pitch the Wyeast 3278 directly into the fermenter or you can rack the beer to a secondary fermenter and pitch the Wyeast 3278.

Let the fermenter sit for 6 months.

Bottle or Keg your beer. If you like a clear beer I recommend cold crashing for 2 days prior to doing so.

Adding Fruit to a Sour Beer

If you want to add fruit to your beer, raspberries always work well with sours however the choice is yours. Frozen fruit is what I recommend starting out as there is less work involved.

There are numerous ways and times you can add your fruit. The simplest method that will give you nice results is to add your fruit a month before you are done fermenting. So in this case add it at the 5 month mark.

You can add the fruit directly to the fermenter or again rack it over to a new fermenter. The amount of fruit you use is your call, but for a sour beer most recommend 1lb of fruit per 1 gallon of beer so in this case 5lbs of fruit. But anywhere from 1lb – 5lbs of fruit will work just fine.

Here is a very good post on exactly how to prepare and add fruit to sour beer.

There you have it my friend you now know how to brew a sour beer. If you need ingredients here is a list of online vendors I recommend. As for equipment I brew on the all-in-one systems, they are my favorite type of systems for a whole host of reasons; you can learn about the all-in-one brewing systems on this post.

If you have any questions on brewing this beer feel free to leave a comment and I will get back to you.

Now go get your brew awwnn…

Cheers Big Robb is Out!